Working with eWood

eWood® is a new material similar to wood but made entirely from recycled plastics.

Working with eWood® is easy and here are a few tips and tricks to help you make the most of this terrific new wood alternative;

- eWood® cuts like Hardwood

- Use a pilot hole for screws

- Use hardwood drill bits

- An electric saw is preferable

- You can only nail eWood® if you predrill the holes. We recommend the use of screws or bolts.

- Stainless Steel or Galvanised screws or bolts are recommended for outdoor use.

Recommendations for cutting eWood

Safety

Ensure the appropriate safety equipment (PPE) is worn at all times as per working with timber and ensure all work is performed in a ventilated area.

Cutting

eWood can be cut with the same tools as used for cutting timber including hand, circular, band, jig and sabre saws. We recommend the use of a circular saw or equivalent mitre/compound/docking saw. Although a standard blade will be adequate for the occasional use, for commercial applications we would recommend the use of a Tungsten Carbide blade with a high number of teeth (i.e. 305mm OD – 72 to 100 teeth).(see example pics below)

When cutting eWood it is recommended to make sure the blade is not allowed to heat up to much as this will make the cut harder to achieve and may cause the blade to grab. It is therefore recommended that if multiple cuts are required allow the blade to cool down before continuing to cut and/or use a suitable blade cooling lubricant. Also ensure the blade and material is clear of all plastic swarf whenever possible.

Recommendations for glueing eWood

Safety

Ensure the appropriate safety equipment (PPE) is worn as recommended by the adhesive manufacturing and ensure all work is performed in a well-ventilated area.

Glueing

eWood can be effectively glued using a wide range of adhesives.

Before choosing an adhesive, it is recommended to review the details on the packaging ensuring the manufacturer has confirmed the adhesives effectiveness on bonding styrenic plastics.

For the most effective bond please also ensure all instructions supplied by the manufacturer are correctly followed.

Following are just a few examples of suitable adhesive types/brands that have been used to bond eWood effectively:-

Loctite Super Glue, Selleys Kwik Grip Advanced, Selleys Plastics Glue & Bostik Multi Bond.

Recommendations for drilling eWood

Safety

Ensure the appropriate safety equipment (PPE) is worn at all times as per working with timber and ensure all work is performed in a ventilated area.

Drilling

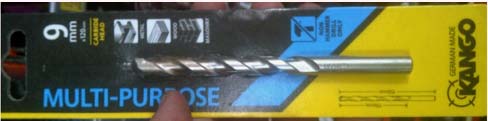

eWood can be drilled with the same bits as used for drilling timber/metal but we have found through extensive research and experience that the preferred bit to use is a Kango Multi-purpose (See Pic).

In general we recommend the use of a drill set at a relatively high speed and a bit with flutes that allow the removal of as much material as possible.

If a large number of holes are required we recommended allowing the bit to cool down whenever possible.